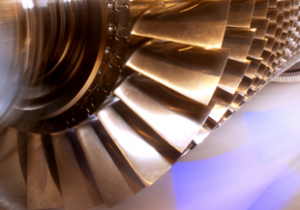

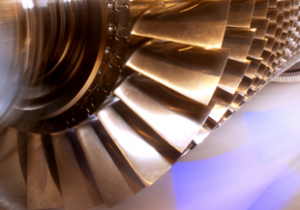

Instrumentel’s advanced wireless turbine telemetry system has demonstrated its ability to transmit turbine blade data from inside sealed turbine units tested at up to 100,000 rpm, dispensing of the need for unreliable mechanical slip rings.

The wireless Instrumentel Turbine Telemetry System (ITTS) has been designed specifically to address the challenges of turbine telemetry, by collecting and transmitting turbine blade strain and temperature data collected from gas turbines during spin-up testing. The system is comprised of up to twelve individual battery powered data acquisition modules, usually mounted in the balancing grooves of the turbine ring.

Each module samples data from sensors, usually mounted to an individual turbine blade, giving multiple inputs for turbine monitoring. Sensor data is transmitted wirelessly to the Instrumentel Diagnostics Hub through one of two antennae mounted on the turbine assembly, with the system automatically switching between antennae as required.

This dual antenna “virtual slip ring” system removes blind spots, and therefore provides data from the full rotational cycle of the turbine.

The Instrumentel Turbine Telemetry System is applicable to any application requiring collection and transmission of operating data from rotating parts within sealed units, and variants of the system have been used for turbo and electrical motor telemetry.

At the core of the Instrumentel turbine telemetry system is a battery powered data acquisition<br/> and wireless transmitter module or “tag”<br/> designed to fit in standard balancing grooves.

This tag samples data from a sensor mounted to<br/> the turbine blade being measured prior to transmitting data wirelessly to the Machine Diagnostics Unit.

Up to 12 tags can be monitored simultaneously <br/>from within the sealed turbine

Turbine Telemetry Case Study

The wireless Instrumentel Turbine Telemetry System (ITTS) has been designed specifically to address the challenges of turbine telemetry. This Case Study reports the use of the ITTS to collect and transmit turbine blade strain data collected from a gas turbine during spin-up testing.